The award recognises ROCKWOOL’s technology innovation and implementation of sustainable processes leading to more than 70 percent CO2 emission reductions from its Danish manufacturing facilities.

The innovation award for sustainable processes highlights the results of ROCKWOOL’s multi-year engineering efforts to develop industry-leading fuel-flexible melting technology. This technology allows us to shift from coal to less carbon-intensive fuels such as natural gas or biogas in the facilities where this technology is being used.

Hanne Bach, Chairman of the Danish jury for the European Business Award for the Environment, comments, “The award goes to ROCKWOOL. They have demonstrated how engineering to develop new technologies can help solve some of the climate challenges that we face today”.

Developed and first implemented at our factories in Denmark, the fuel-flexible technology will contribute to ROCKWOOL achieving its recently announced global decarbonisation targets that have been verified and approved by the Science Based Targets initiative (SBTi).

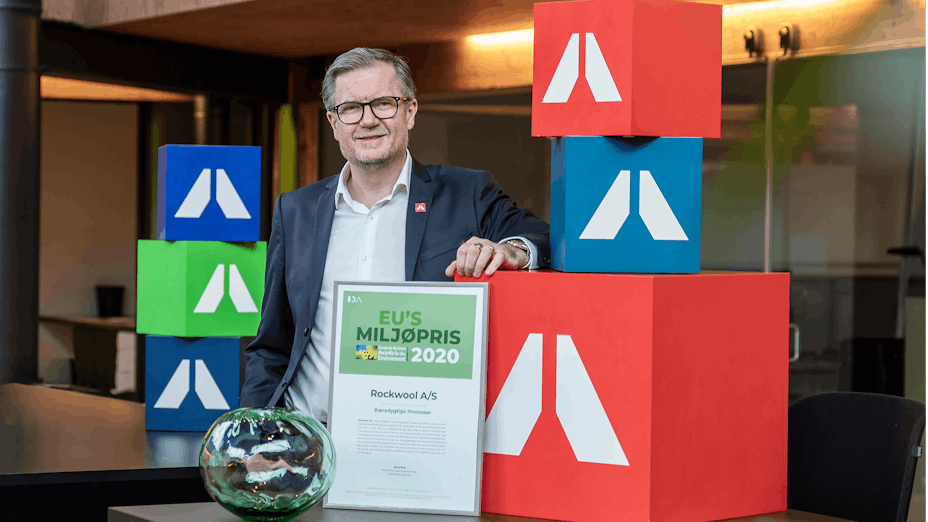

Bjørn Andersen, Senior Vice President for Group Operations & Technology at ROCKWOOL Group comments, “Winning this award testifies to the fact that sustainability is at the core of our business. The engineering and technology innovations this award recognises build on our decades-long efforts to improve the energy efficiency and reduce the environmental impact of our own operations. More than 50 engineers in Denmark have been working on the patented fuel-flexible melting technology being highlighted today. Ready-made solutions did not exist, so we invented them ourselves”.

As ROCKWOOL is the 2020 Danish winner for sustainable processes, the company automatically qualifies for the European competition, where the winners will be selected in 2022.

Commenting on ROCKWOOL’s global technology innovation, Bjørn Andersen continues, “Because we operate in many countries around the world, we also know that we cannot put all our technology eggs in one basket. That is why ROCKWOOL has also developed a large-scale electric melting technology that is well-suited in countries where the electricity grid is already low carbon. At ROCKWOOL’s factory in Moss, Norway, for example, we have recently inaugurated the industry’s largest electric melter, reducing emissions by approximately 80 percent compared to the previous technology used there”.

ROCKWOOL’s road to decarbonise production

In addition to converting our two Danish factories to natural gas in 2020 and certified climate-neutral biogas in 2021, we will also in 2021 convert one of our factories in Poland to natural gas and start up operations at our newest facility under construction in the United States with natural gas rather than coal. We plan to convert other factories using this fuel-flexible melting technology from coal to gas over the next few years. The learnings we gain from these multiple innovations and our ongoing energy efficiency efforts will be applied elsewhere in ROCKWOOL’s global operations.

The European Business Award for the Environment

Read more here at the EU website, and here at The Danish Society of Engineers.